In high-risk industries such as oil and petrochemicals, large quantities of flammable substances, including crude oil, natural gas, and hydrogen, are present throughout the value chain. When mixed with air and exposed to an ignition source, an explosive atmosphere can easily form.

Battery systems and Battery Management Systems (BMS), which play a critical role in providing stable power to key equipment, are inherently sensitive to heat, pressure, and mechanical stress, factors that can trigger thermal runaway, short circuits, or even fires, turning batteries into potential ignition sources and introducing serious safety hazards.

Against this backdrop, compliance with ATEX and IECEx explosion-proof certification standards is not only the minimum requirement for operational safety and regulatory conformity but also a foundational element for preventing catastrophic incidents.

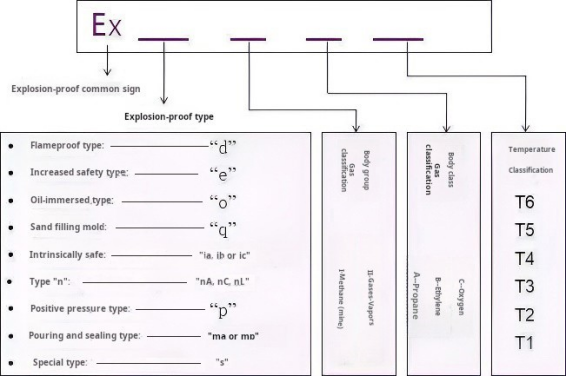

Incorporating multiple intrinsic safety and physical isolation mechanisms to deliver system-level explosion protection, the Gerchamp G-TH-Ex Explosion-proof Battery Monitoring System is designed in accordance with globally recognized ATEX and IECEx standards. Devices that pass IECEx/ATEX explosion protection certification are assigned specific codes. These markings represent the equipment's verified explosion protection level and serve as an authoritative endorsement for safe use in hazardous environments.

The G-TH-Ex is certified with the following explosion-proof codes:

[Ex eb mb IIC T5 Gb] & [Ex tb IIIC T100°C Db]

Explanation of Coding System in ATEX/IECEx Certification

eb (Increased Safety): Designed to prevent arcs, sparks, and dangerous temperatures under normal operation and overload conditions, ensuring that components do not become ignition sources.

mb (Encapsulation): Critical components are encapsulated to prevent arc formation and explosion risk.

tb (Protection by Enclosure): The system uses a sealed enclosure to prevent dust ingress and to limit surface temperature, making it suitable for explosive dust atmospheres.

Group IIC: Indicates suitability for highly explosive gases such as hydrogen and acetylene, common in oil and petrochemical environments.

T5 / T100°C: Ensures that the surface temperature of the equipment does not exceed 100°C, remaining well below the ignition temperatures of most flammable gases to minimize fire risk.

Gb / Db: Certifies the equipment for use in Zone 1 and Zone 2 hazardous areas, guaranteeing safe operation in environments with frequent or occasional explosive atmospheres.

In explosive environments, even the smallest design oversight can have catastrophic consequences. The G-TH-Ex BMS from Gerchamp meets the rigorous criteria of the ATEX and IECEx standards and is certified for use in Zone 1 and Zone 2 classified areas.

By employing eb, mb, and tb explosion-proof design principles and strictly regulating surface temperature, the G-TH-Ex is engineered to operate safely in environments where explosive gases like hydrogen and acetylene are present. Beyond intrinsic safety, the system also provides precise real-time monitoring of battery status, offering early warnings to preempt faults or thermal events.

This multi-layered safety strategy delivers robust energy protection tailored to the stringent safety demands of the oil and petrochemical industries.

Contact us to learn more: sales@gerchamp.com